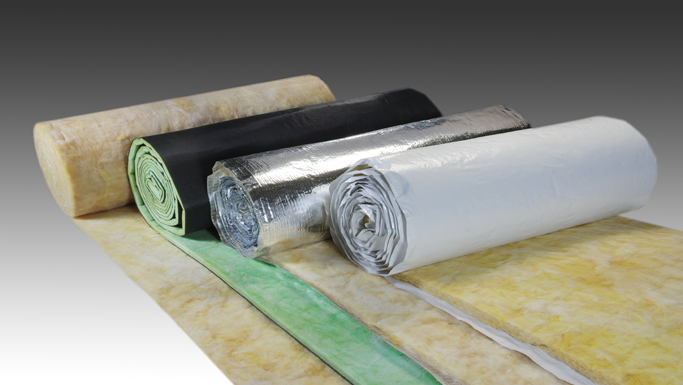

When used as a facing material for substrates like fiber glass, rock wool, foam board, rubber foam, PU/PIR panels, gypsum board, and ceiling panels, Alu Foil Facing plays a crucial role in enhancing insulation performance, waterproofing, and durability. The selection of composite materials for aluminum foil is primarily driven by end-use requirements such as strength, temperature resistance, water resistance, and environmental friendliness. Below is a detailed breakdown of its four major categories of composite materials, along with their key products and functional benefits.

I. Plastic Materials: The Most Versatile Composite Choice

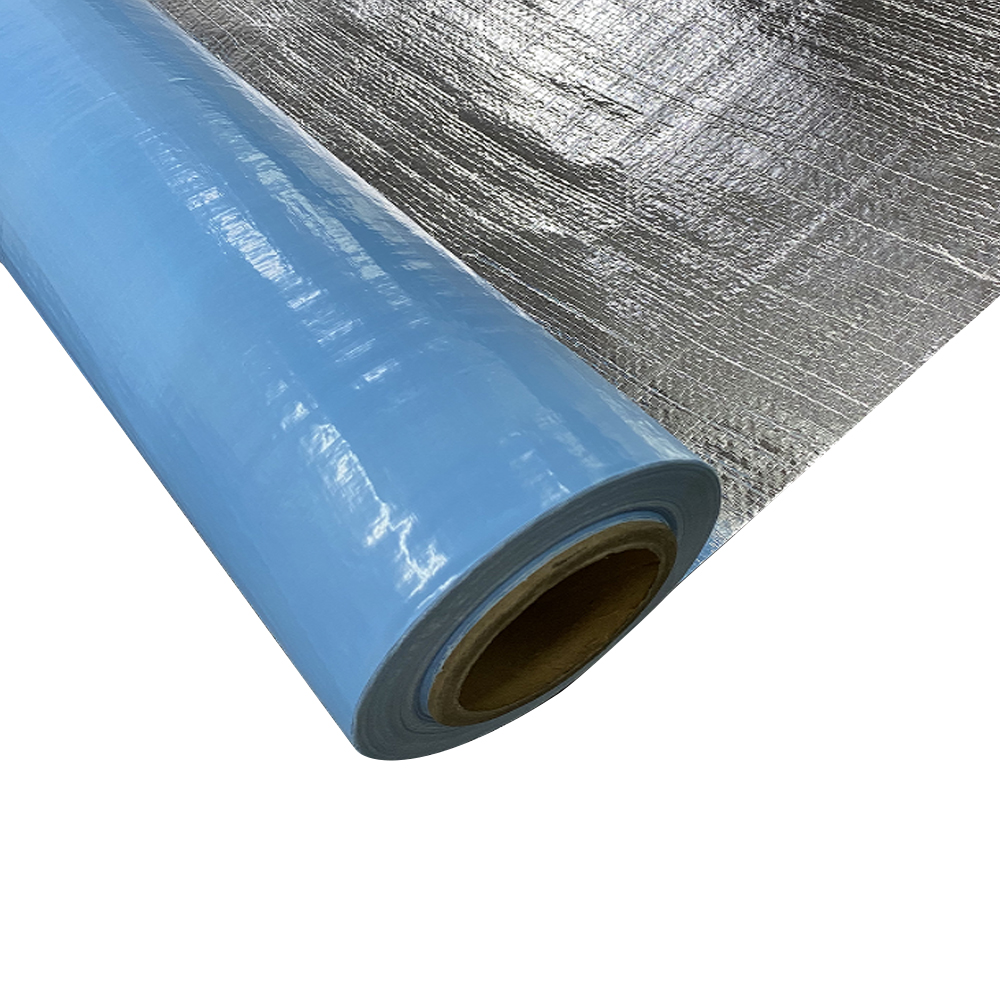

Aluminum foil laminated with plastics significantly improves the material’s flexibility, water resistance, and mechanical strength, making it the preferred option in industrial insulation and packaging applications.

1. Polyethylene (PE)

Key Products: Alu Foil Woven Fabric, Alu Foil + PE + PET + PE, Alu Foil + PE, Alu Foil + Scrim + PE

Advantages: Cost-effective, excellent flexibility, and strong chemical resistance.

Applications: Widely used in building insulation layers, food packaging (e.g., fresh-keeping bags), and pipe wrapping for its reliable moisture barrier.

2. Polypropylene (PP)

Key Products: Alu Foil + PP Film, Alu Foil + PP Nonwoven

Advantages: Higher temperature resistance than PE (approximately 100-120℃) and better rigidity.

Applications: Suitable for high-temperature food packaging (e.g., microwaveable meal boxes) and automotive interior heat insulation components.

3. Polyvinyl Chloride (PVC)

Key Products: Alu Foil +Scrim+MPET /MPET+Scrim+kraft paper

Advantages: Superior waterproofing and flame retardancy. Note: It has relatively low environmental compatibility.

Applications: Commonly used in industrial waterproofing membranes and temporary outdoor covering materials.

4. Polyethylene Terephthalate (PET)

Key Products: Alu Foil + PET + PE

Advantages: High strength, excellent high-temperature resistance (around 150℃), and good aging resistance.

Applications: Ideal for high-end food packaging (e.g., tea bags) and shielding packaging for electronic components.

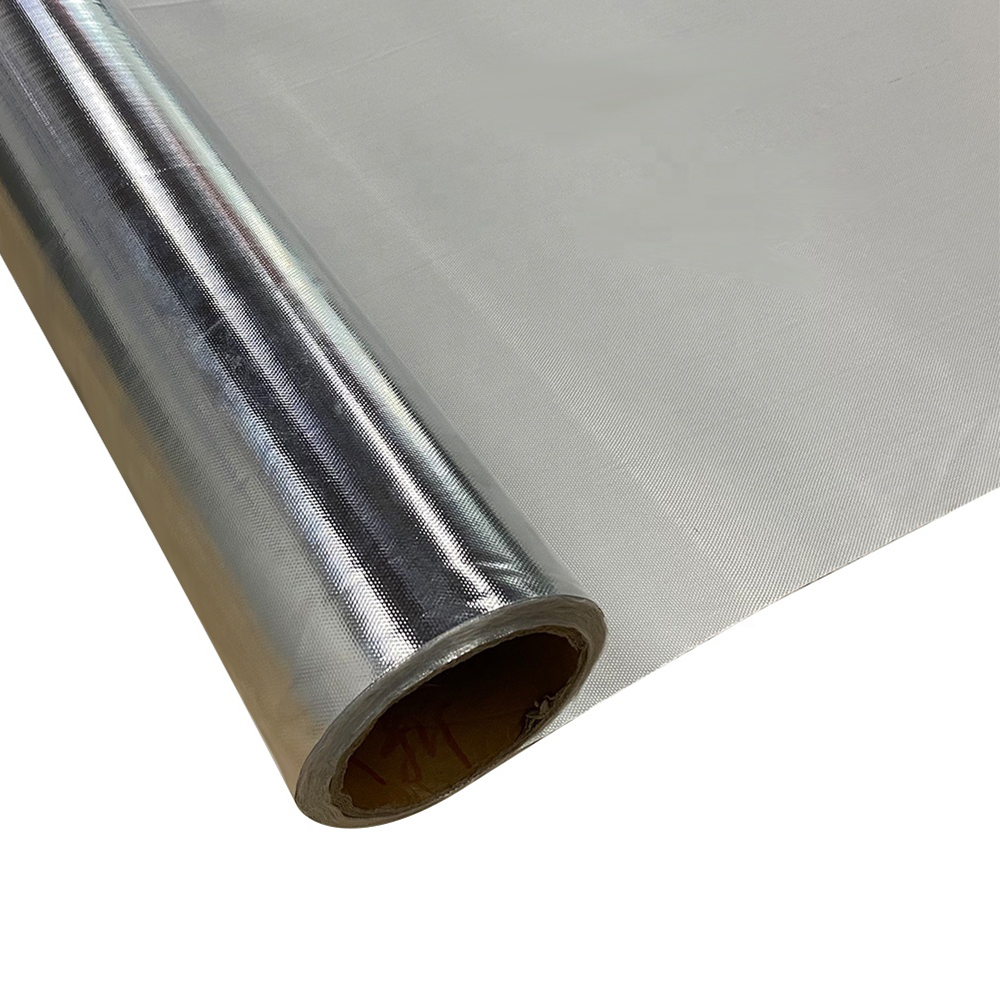

II. Fiber/Textile Materials: Enhancing Strength and Heat Resistance

Fiber and textile composites boost aluminum foil’s tensile strength and temperature resistance, making them particularly suitable for industrial insulation and construction.

1. Glass Fiber

Key Products: Alu Foil + Fiberglass Fabric, Alu Foil + Fiberglass Tissue, Alu Foil + Fiberglass Fabric + Nonwoven

Advantages: Exceptional high-temperature resistance (≥200℃), top-tier fire performance, and high mechanical strength.

Applications: Core composite material for high-temperature pipeline insulation, building firewalls, and thermal insulation in boilers and kilns.

2. Polyester Fiber (PET Fiber) Nonwoven fabric or woven fabric

Key Products: Alu Foil + PET Nonwoven

Advantages: Good flexibility, high tensile strength, and strong weather resistance.

Applications: Used in external wall insulation for buildings and sound/heat insulation layers in automobiles.

III. Paper Materials: Cost-Effective and Printable

Combining aluminum foil with paper offers cost efficiency and excellent printability, making it a go-to choice for packaging, especially in the food and daily necessities sectors.

1. Kraft Paper

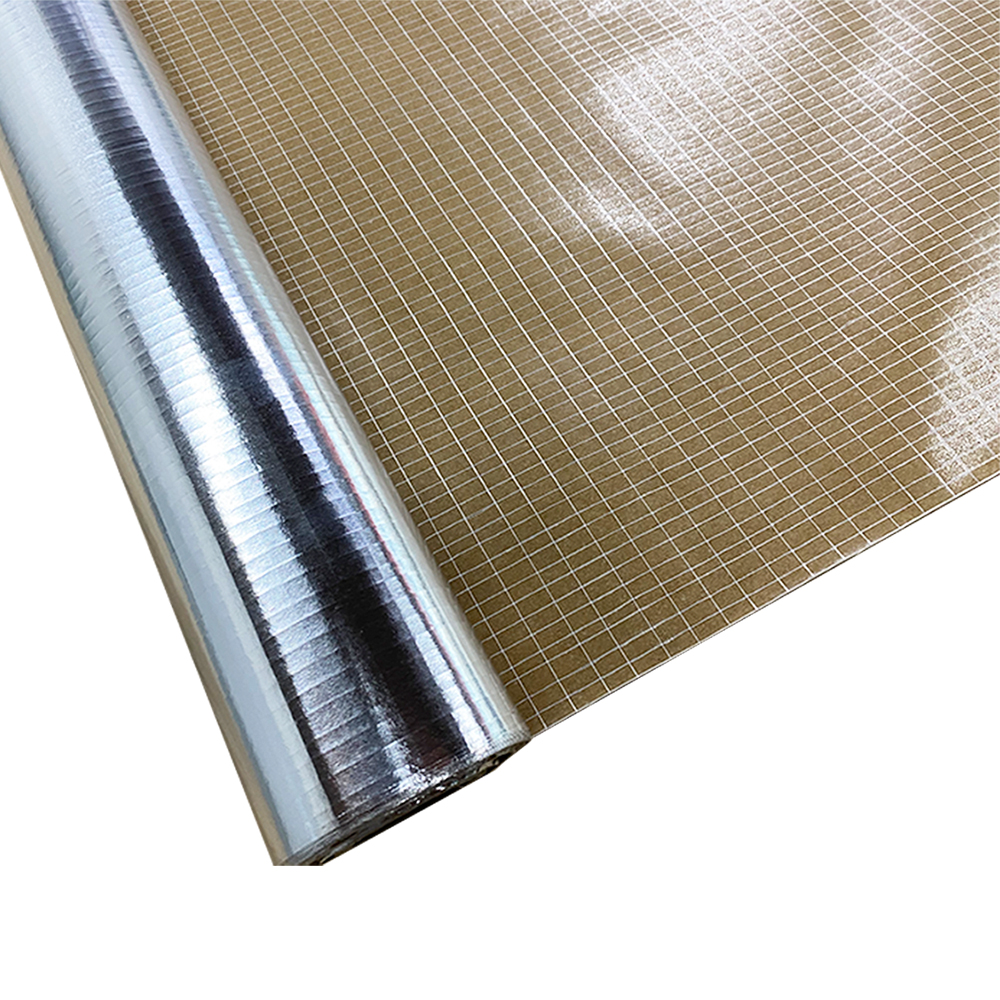

Key Products: Alu Foil + Kraft Paper, Alu Foil + Scrim + Kraft Paper, PE + Kraft Paper + Scrim + Kraft Paper + PE

Advantages: High strength and tear resistance, with dual functions of moisture protection and printability.

Applications: Frequently used in food packaging (e.g., chocolate and cookie wrappers) and cigarette inner packaging.

IV. Metal Materials: For Special Functional Requirements

Composites with other metals are designed to enhance specific properties such as conductivity, corrosion resistance, and shielding, targeting high-end industrial scenarios.

Copper Foil/Tin Foil: When combined with aluminum foil, they improve conductivity or corrosion resistance. Applications include electromagnetic shielding layers for electronic devices and corrosion-resistant pipeline insulation in marine engineering.

Metal Mesh (Steel Mesh, Aluminum Mesh): Embedded in aluminum foil to enhance mechanical strength and puncture resistance. Suitable for insulation materials in harsh outdoor environments and explosion-proof packaging.

If you need to adapt this press release for a specific market (e.g., emphasizing environmental standards for European clients or cost advantages for Asian markets), I can help refine a market-tailored version of the press release with adjusted key points and terminology. Would you like to specify a target market or focus area for further optimization?

Jinan United Perfect Builing Materials is a professional manufacturer of laminated & coated facings for fiber glass, rock wool, foam board, rubber foam, PU/PIR panel, gypsum board, ceiling panels etc. for more than 20 years.

At present we have been producing the following facers/ veils with BS476, ASTM E84 test certificates etc.

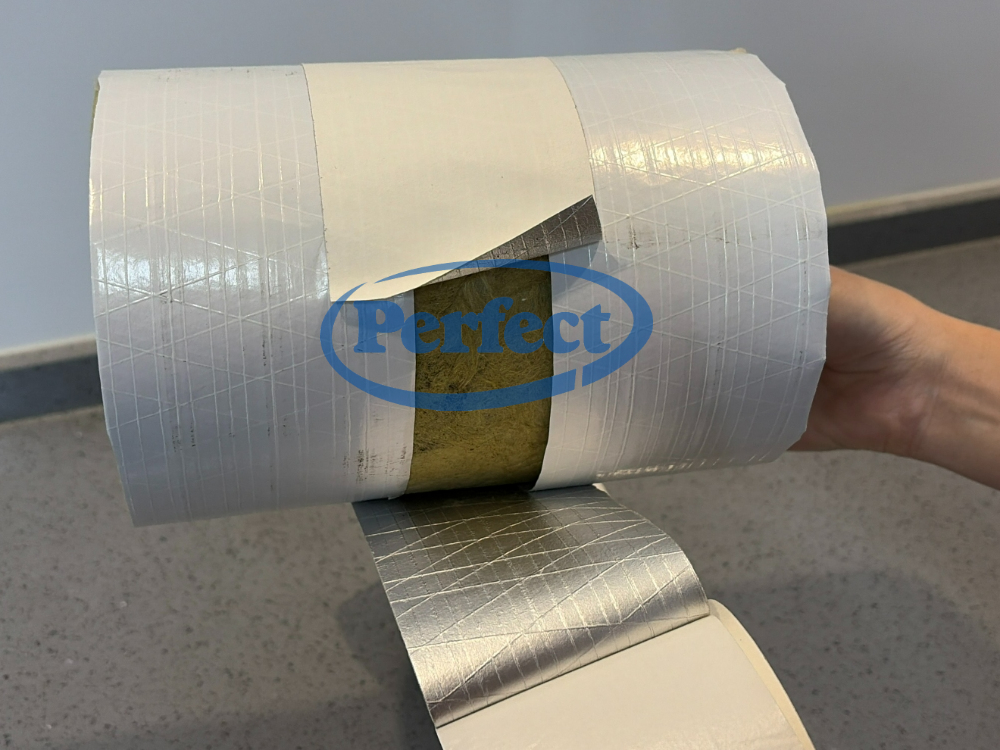

1, Laminated & reinforced Facings (FSK, Alu-glass, heat sealing foil, WMP series, sarking);

2, Alu + PET, VMPET + PE, Alu + PE, PET + Alu + PE;

3, Alum foil tape, FSK tape, aluglass tapes;

4, Fiberglass non-woven/ tissue/ veils, coated fiberglass, such as BGT, BGF, silicone etc.;

5, Coated Fiberglass Mat for Gypsum board, ceiling, insulation facer etc.

Welcome to technical exchanges and feel free to request free samples

Phone / Whatsapp: +8613426130536