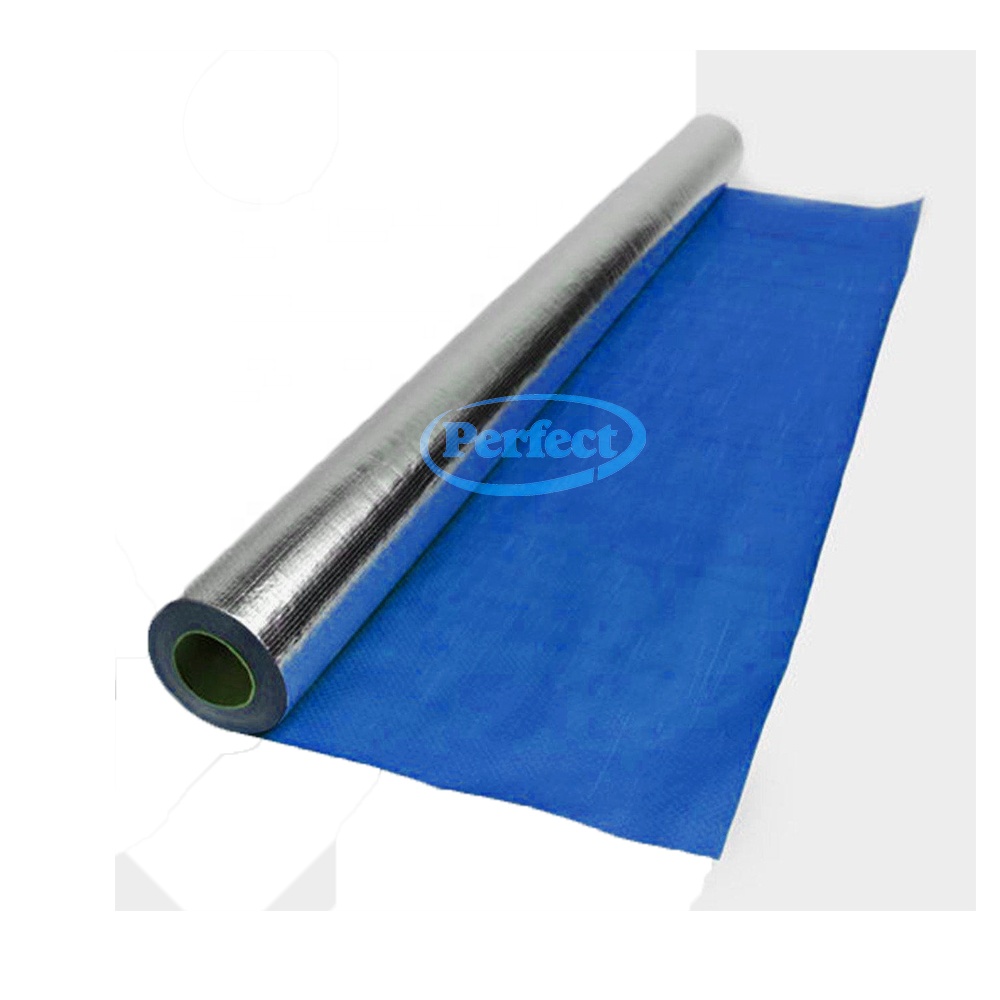

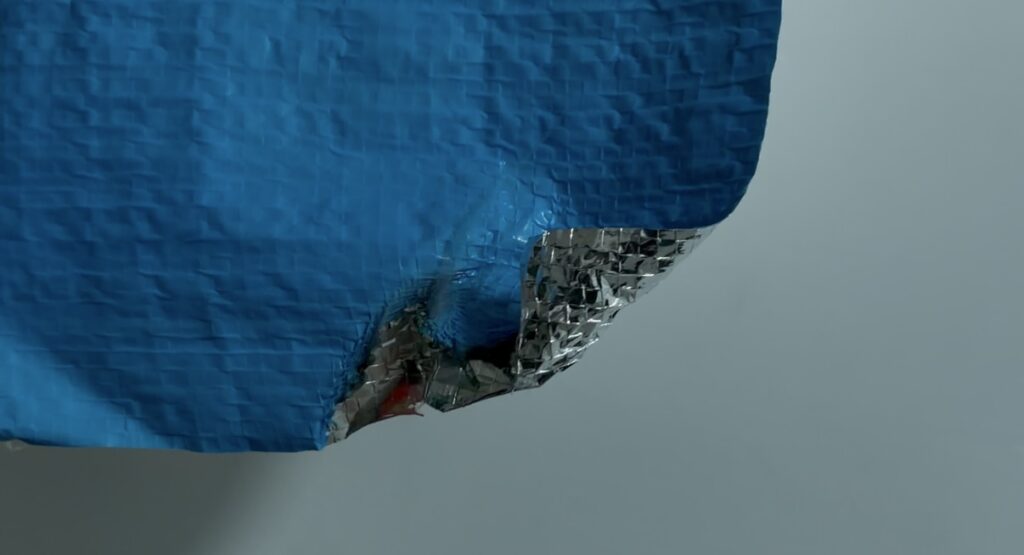

Aluminum Foil + Blue Woven Fabric (Roof Sarking/Building Wrap): Core Weatherproofing & Thermal Insulation Material for Australian Construction

Aluminum foil + blue woven fabric (commonly known as roof sarking or building wrap) is a critical “weatherproofing + thermal insulation” material in Australian construction. It must meet the core fire resistance requirements of the AS/NZS 4859 series and is widely used in the envelope structures of residential, commercial, and industrial buildings.

I. Main Application Scenarios

Roof Enclosure: Laid between roof trusses and roof tiles to block rainwater penetration, reduce heat transfer, and prevent condensation accumulation.

Wall Insulation: Serves as an external wall wrap to encase wall frames, enhancing airtightness and watertightness. When paired with insulation layers, it significantly improves energy efficiency.

Commercial Building Support: Applied in the roof/wall systems of industrial plants, shopping malls, and other commercial properties. It separates structural layers from the external environment, protecting internal building materials from moisture damage.

Special Scenarios: Salt spray-resistant modified versions are selected in coastal areas to meet the corrosion resistance requirements of marine climates.

II. Core Fire Resistance Standards (Australian Mandatory Requirements)

Basic Fire Resistance Standard: Must comply with AS/NZS 4859.1 (Test Methods for Flammability of Flexible Building Coverings), meeting the “self-extinguishing” requirement. This means the material stops burning within a specified time after the ignition source is removed.

Classification Requirements: Classified into different fire resistance grades based on building height and usage, with common grades being Group 1 or Group 2 (Group 1 offers superior fire resistance). High-rise residential buildings, hospitals, schools, and other crowded buildings require Group 1 grade.

Additional Testing: Some states (e.g., Victoria) mandate additional compliance with AS/NZS 3837 (Toxicity of Fire Effluents from Building Materials). This standard limits the release of toxic gases during combustion to ensure safe evacuation.

III. Core Application Requirements (Aligned with Fire Resistance Standards)

Compliance Certification: Materials must pass testing by laboratories accredited by Australia’s SAI Global or JAS-ANZ. A valid compliance certificate is mandatory before on-site application.

Installation Specifications: Must adhere to AS/NZS 4200 (Installation of Metal Roof and Wall Cladding). Ensure no damage during laying and tight sealing at overlaps to avoid compromising fire resistance and waterproofing performance.

Regional Differences: In high-temperature regions such as Western Australia and the Northern Territory, some projects require materials to meet dual indicators of “fire resistance + UV aging resistance” to extend service life.

Jinan United Perfect Builing Materials is a professional manufacturer of laminated & coated facings for fiber glass, rock wool, foam board, rubber foam, PU/PIR panel, gypsum board, ceiling panels etc. for more than 20 years.

At present we have been producing the following facers/ veils with BS476, ASTM E84 test certificates etc.

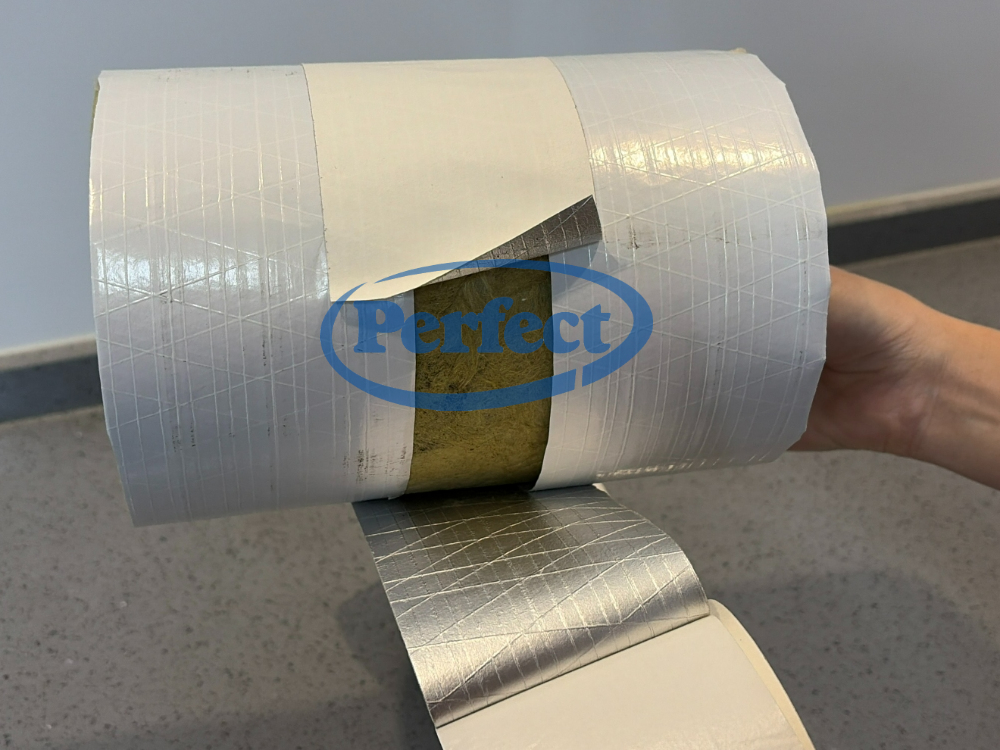

1, Laminated & reinforced Facings (FSK, Alu-glass, heat sealing foil, WMP series, sarking);

2, Alu + PET, VMPET + PE, Alu + PE, PET + Alu + PE;

3, Alum foil tape, FSK tape, aluglass tapes;

4, Fiberglass non-woven/ tissue/ veils, coated fiberglass, such as BGT, BGF, silicone etc.;

5, Coated Fiberglass Mat for Gypsum board, ceiling, insulation facer etc.