ASTM E84, UL 723, BS 476, AS/NZS 1530, and GB 8624 are core flame retardant standards for building materials in different regions.

The flame retardancy ratings of glass wool, rock wool, and foil-faced products under these standards depend on material characteristics and the focus of each test.

Below is a detailed interpretation:

1. ASTM E84 (USA)

Core Scope: The primary standard in North America for evaluating the surface burning characteristics (flame spread and smoke development) of interior building finish materials. Also known as the “Steiner Tunnel Test.”

Key Metrics: Classified using the **Flame Spread Index (FSI)** and **Smoke Developed Index (SDI)**, with red oak (FSI=100, SDI=100) as the benchmark.

Main Classifications: **Class A (FSI ≤ 25), Class B (FSI 26-75), Class C (FSI 76-200); SDI must be ≤ 450 for all classes.**

2. UL 723 (USA)

Core Scope: Developed by Underwriters Laboratories (UL). Technically nearly identical to ASTM E84, both utilizing the “Steiner Tunnel Test” method.

Key Feature: Test results are mutually recognized. The **UL 723 Class A/B/C** classification criteria are identical to ASTM E84. It is often considered the “UL version” of ASTM E84.

Application Scenario: Both are widely accepted for flame retardancy certification of building finish materials in the North American market. Manufacturers can choose based on requirements.

3. BS 476 (UK)

Core Scope: A traditional UK system for testing the fire performance of building materials (not a single standard). Covers finish materials, load-bearing elements, etc. Partially superseded by European EN standards but still commonly used for historical projects.

Key Parts & Classifications:

BS 476-6/7: Pertains to finish materials. Classified by flame spread properties, with **Class 0** being the highest, followed by Class 1/2/3/4.

BS 476-20/21/22: Pertains to load-bearing elements, evaluating fire resistance (rated in hours, e.g., 0.5h, 1h, 2h).

4. AS/NZS 1530 (Australia/New Zealand)

AS/NZS 1530.1: Test for Non-Combustibility – Determines if a material is non-combustible. Materials must not sustain combustion beyond a specified time.

AS/NZS 1530.2: Flammability – Measures flame propagation, heat release, and smoke density. Applicable to flexible sheets or textiles (e.g., curtains, wall coverings), but not suitable for materials that melt and shrink significantly.

AS/NZS 1530.3: Simultaneous Determination of Ignitability, Flame Propagation, Heat Release and Smoke Release – The core fire test standard in the Australian/New Zealand market, measuring four key parameters simultaneously.

AS/NZS 1530.4: Fire Resistance – Assesses the ability of building elements (e.g., walls, floors, doors) to maintain integrity, insulation, and stability under fire conditions for a specified duration.

5. GB 8624 (China)

Core Scope: The mandatory fundamental standard in China for classifying the burning behavior of building materials and products. Covers all building materials.

Key Metrics: Employs a comprehensive classification based on “Burning Behavior Grade + Smoke Production Characteristics + Flaming Droplets/Particles.” Grades from highest to lowest are A1, A2, B1, B2, B3.

Core Grade Definitions: A1/A2 are non-combustible materials, B1 are flame-retardant materials, B2 are combustible materials, B3 are flammable materials.

Jinan United Perfect Builing Materials is a professional manufacturer of laminated & coated facings for fiber glass, rock wool, foam board, rubber foam, PU/PIR panel, gypsum board, ceiling panels etc. for more than 20 years.

At present we have been producing the following facers/ veils with BS476, ASTM E84 test certificates etc.

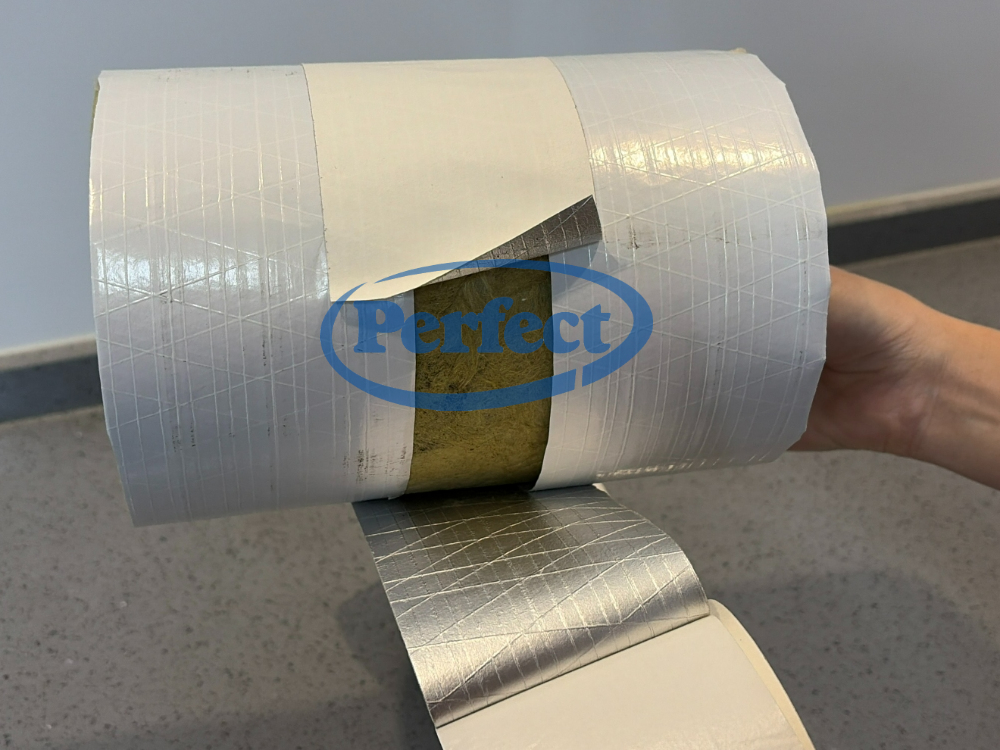

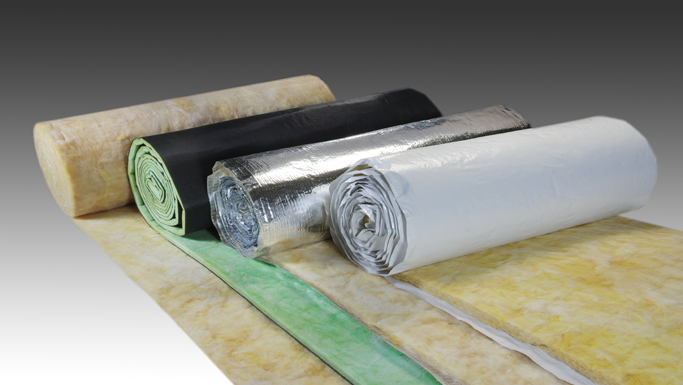

1, Laminated & reinforced Facings (FSK, Alu-glass, heat sealing foil, WMP series, sarking);

2, Alu + PET, VMPET + PE, Alu + PE, PET + Alu + PE;

3, Alum foil tape, FSK tape, aluglass tapes;

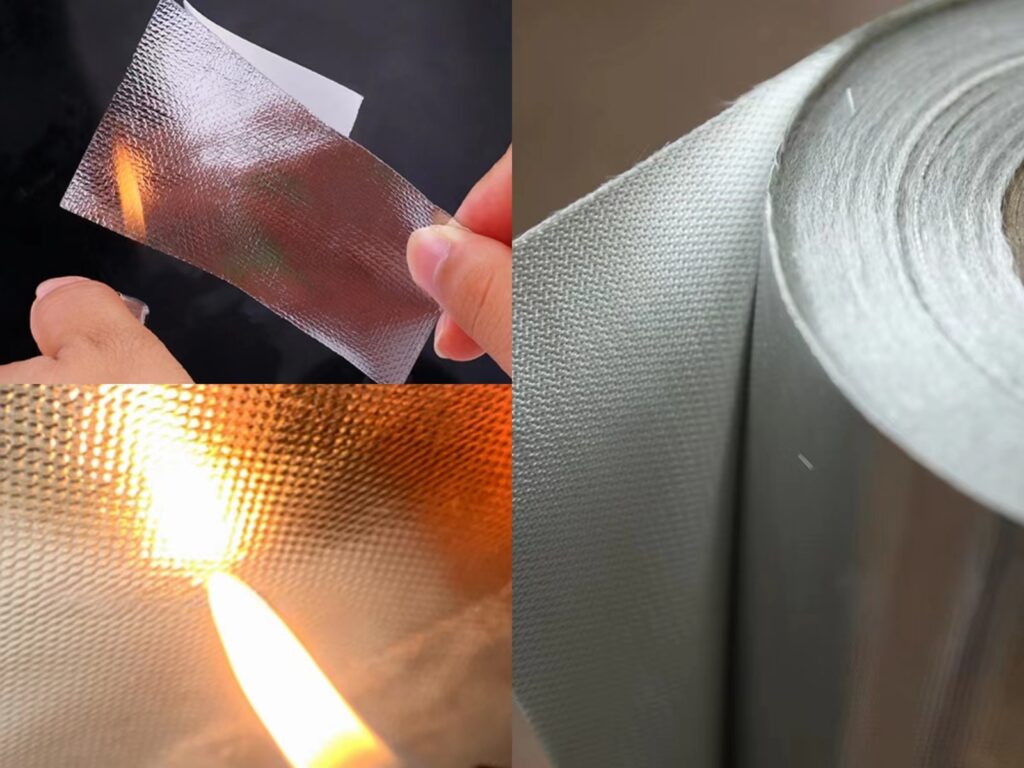

4, Fiberglass non-woven/ tissue/ veils, coated fiberglass, such as BGT, BGF, silicone etc.;

5, Coated Fiberglass Mat for Gypsum board, ceiling, insulation facer etc.